-

PTFE guide belt wearing strips

PTFE guide belt advantages: 1. Good abrasion resistance, long lifetime.2. High structure strenght , certain degree elasticity.3. Without metallic contact of the sliding surfaces.4. Control the machine’s vibration.5. Absorb the size’s load.6. Enlarge the clearance of seal’s extru...Read More -

PTFE Graphite Sheet

PTFE filled with graphite sheet,is manufactured by molding process with ptfe granular ptfe resin and graphite. With excellent characteristics of chemical corrosion resistance, weathering resistance, dielectric superiority, strong tensile strength, low friction and aging resistance, it is suitable...Read More -

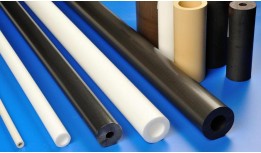

PTFE Glass and Carbon/Graphite Filled

PTFE is a fluorocarbon solid, as it is a high-molecular-weight compound consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons demonstrate mitigated London dispersion forces due to the high electronegativity of fluor...Read More -

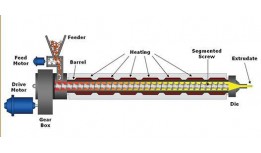

Hot Melt Extrusion

Hot-melt extrusion (HME) is an established process that has been used since the early 1930s, predominately in the plastics manufacturing … Hot melt extrusion (HME) is the process of applying heat and pressure to melt a polymer and force it though an orifice in a continuous process. HME is a...Read More -

PTFE, Glass Filled

PTFE Glass-Filled – Milled glass fibers have the least effect on chemical and electrical properties and add greatly to the mechanical properties of unfilled PTFE. Addition of glass improves compressive properties by as much as 40% and improves wear resistance greatly. These compounds resist...Read More -

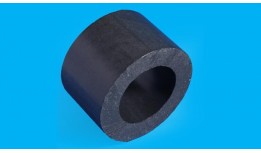

PTFE gasket moulding machine

PTFE gasket moulding machine features:Efficiently producing: 300pieces/h(large size);More energy saving: the total power only 5KW;More friendly to environment: no PTFE powder splashing but powder output automatically;More precise: producing gaskets by controlling the power quantity;More time savi...Read More